What is Thermal Spraying?

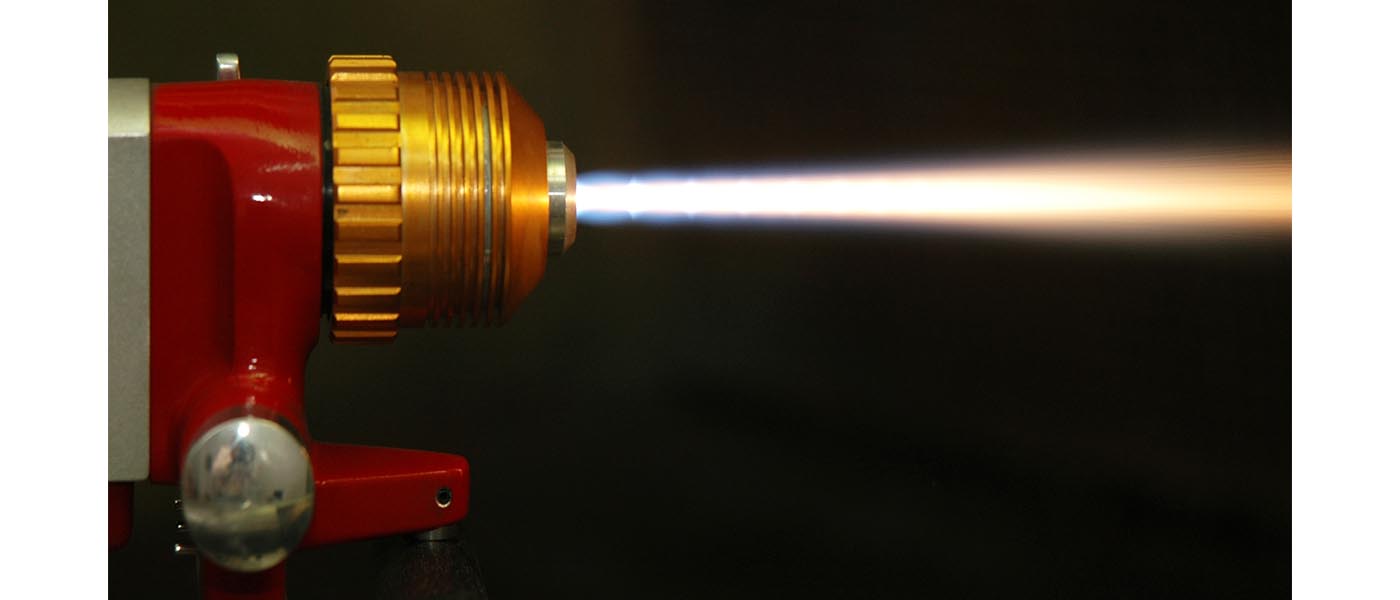

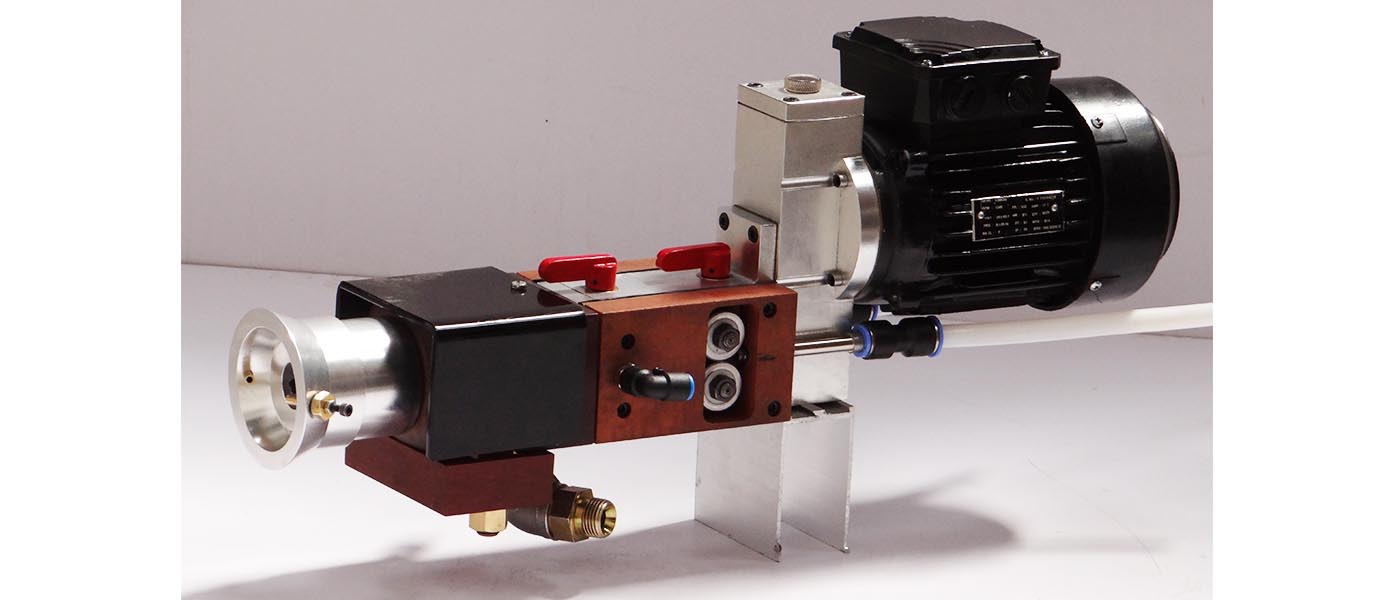

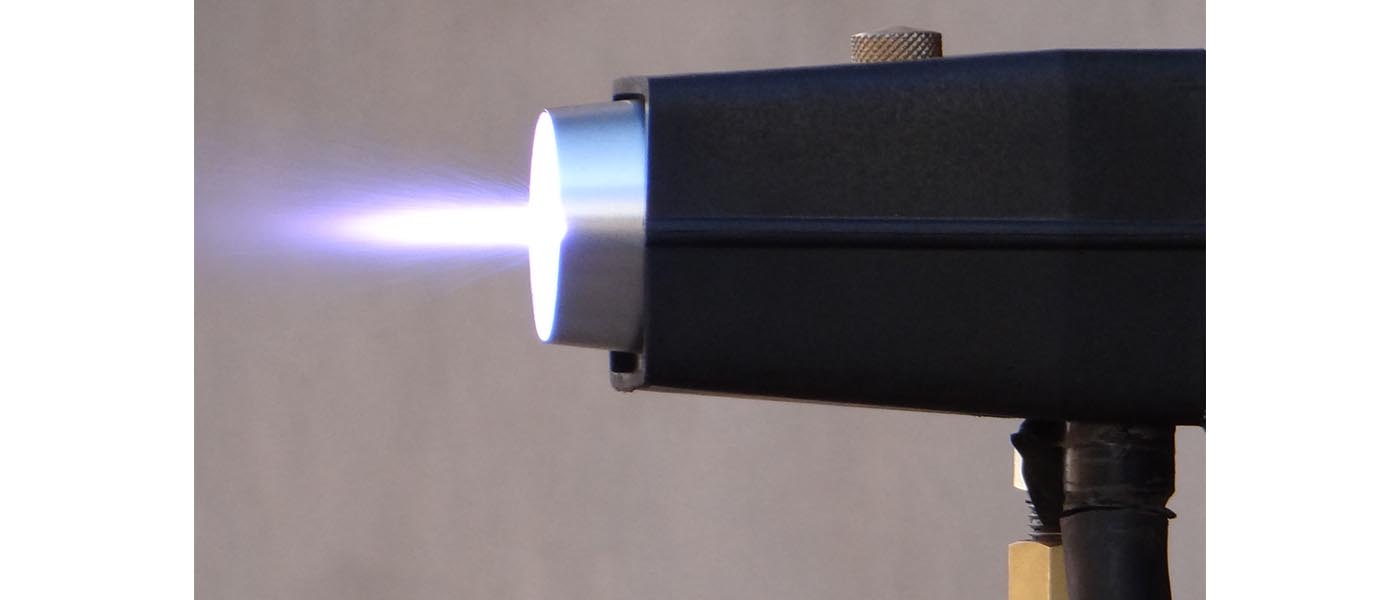

Thermal spraying process is well established, highly cost-effective and extremely versatile technology that is commercially used to produce a wide variety of coatings for adding superior properties and performance qualities to a given engineering surface in which metallic or non metallic (ceramics, carbides, plastics), and mixtures of these materials with unique physical properties are deposited in atomised molten or semi molten condition with help of compressed air or gas on substrate to form a dense, adherent coating.

The coating material may be in the form of wire, powder and powder filled cord to meet a range of physical criteria. The varieties of products and coatings that can be enhanced by thermal spray are virtually limitless. The major advantage of Thermal spray process is that there is no damage/distortion to component and coating is almost instant.

Why use Thermal Spraying ?

- Less expensive Repairs generally cost less than replacing with new parts.

- Wear Resistance Flame sprayed coatings often outwear new parts two to three times.

- Corrosion Resistance Protection from atmospheric and heat corrosion to enhance life of components.

- Saves Time Turn-around time can be as low as a few hours.

- Technological Advances New process innovations allow us to apply exotic wear resistant materials onto less wear resistant parts.

- Safer Flame Spraying does not produce distortion or affect temper of heat treated parts that other repair methods cause.